Technologies

Casting technology is the shortest path from liquid metal to the finished product. We take advantage of this and optimally unite manufacturing processes. We apply consistently efficient manufacturing technologies and support them by cutting-edge IT technologies. This way we avoid buffer stocks. That means tight closed control loops that improve process quality.

We produce sophisticated products, made of aluminum and magnesium alloys, by using most modern, state-of-the-art casting and machining technologies. Integrated, certified quality control loops ensure process stability and specification capability. We produce components which are used throughout the automotive industry.

High Pressure Die Casting

In the die-casting process molten metal is forced at high speed and under high pressure into molds made of tool steel. The filling time of the mold counts less than 6-25 milliseconds and the pressure is up to 1000 bar. This process is characterized by its high productivity and dimensional stability.

We manufacture in this process, complex products such as transmission housings and internal transmission components, steering housings and engine components.

We produce die-cast components that are weldable and suitable for a two-stage heat treatment (T6, T7). The KSM Castings Group developed a special vacuum-pressure casting process, the Controlled Vacuum Casting (CVC®).

Controlled Vacuum Casting (CVC®)

In Controlled Vacuum Casting (CVC®), both the mold and casting chamber are evacuated during mold filling. Several independently controlled vacuum circuits allow a very rapid evacuation procedure and an extremely high negative pressure in the cavity. A specially developed casting plunger prevents leakage between casting and casting plunger.

We use CVC® in the chassis and body area. In CVC®, manufactured components have excellent properties in terms of strength and ductility and are suitable for welding and punching rivets.

Gravity Die Casting

Using the technology of gravity die casting or permanent mold casting, the melt is poured under the influence of gravity through a gating system into the mold. The shrinkage porosity is absorbed by the feeder and overflow system, and the solidification is directed through cooling the mold. Due to the low porosities, we achieve high mechanical properties over a heat treatment.

In gravity die casting, we manufacture a wide variety of complex components with wall thicknesses down to 4 mm and with hollow profiles. The method is suitable for the production of safety components for chassis applications, such as single, or multi-piece sub-frame constructions.

Multi Tilt Casting (MTC®)

In the tilt casting process, Multi Tilt Casting (MTC®), the mold is tilted to the git side at the beginning of the filling. By the subsequent tilting the melt fills the mold. This method provides a lower air lock and allows precise control of the filling speed exactly.

As in gravity die casting, we can fill the mold and direct the process of solidification of the material by cooling.

The KSM Casting Group manufactures both small, compact components, and very large components in the tilt-mold casting process.

Counter Pressure Casting (CPC)

Counter Pressure Casting (CPC) is a further development of conventional low-pressure permanent mold casting. By this newly developed method, the filling of the mold and the solidification of the material can be realized under pressure because the pressures are independently adjustable in the furnace and the mold. In conjunction with a high cooling rate, we achieve excellent mechanical characteristics.

The KSM Castings Group is the world's largest manufacturer of suspension parts in the Counter Pressure Casting Process (CPC). We manufacture Counter Pressure Casting components that are exposed to very high static and dynamic loads.

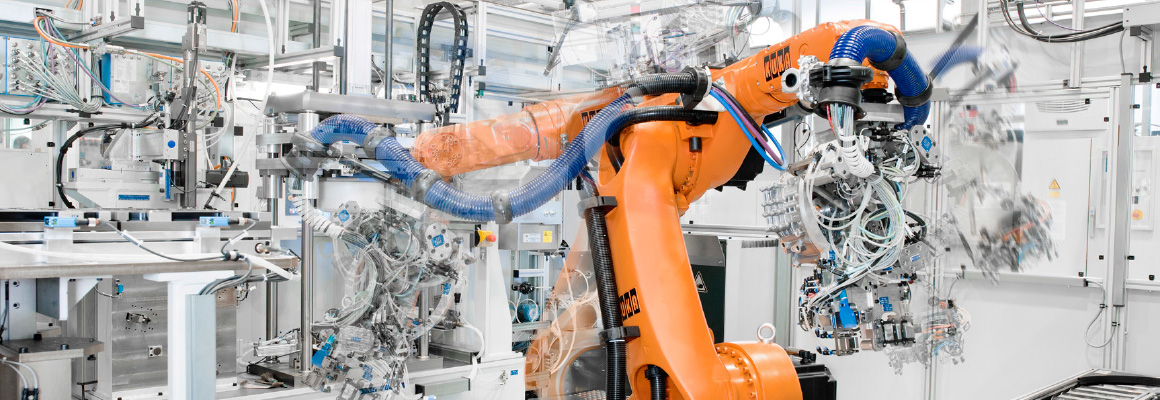

Machining

Everything from a single source, including precision machining of the casting is done on site. The sophisticated nature and challenges of the components we produce require an overall production approach to ensure consistent quality of the product. The precise coordination between the foundry and machining process is necessary to guarantee dimensional accuracy and quality.

Critical casting requirements of the component geometry are maintained and tuned within our internal tooling shop. The dimensional control and quality of the component is integrated into our overall machining process approach from work-holding to machine tools. We utilize extensive in-line gauging and off-line coordinate measuring machines to check and verify all dimensional aspects of the finished component.

The KSM Castings Group ensures the critical coordination between casting- and machining requirements. Over 80% of all components are machined directly on site.

We consider the entire process from the begining, thus ensuring the quality of your product.